Passion project: Andrew Powell putting his love of sci-fi to good use

Published 7:56 pm Wednesday, April 15, 2020

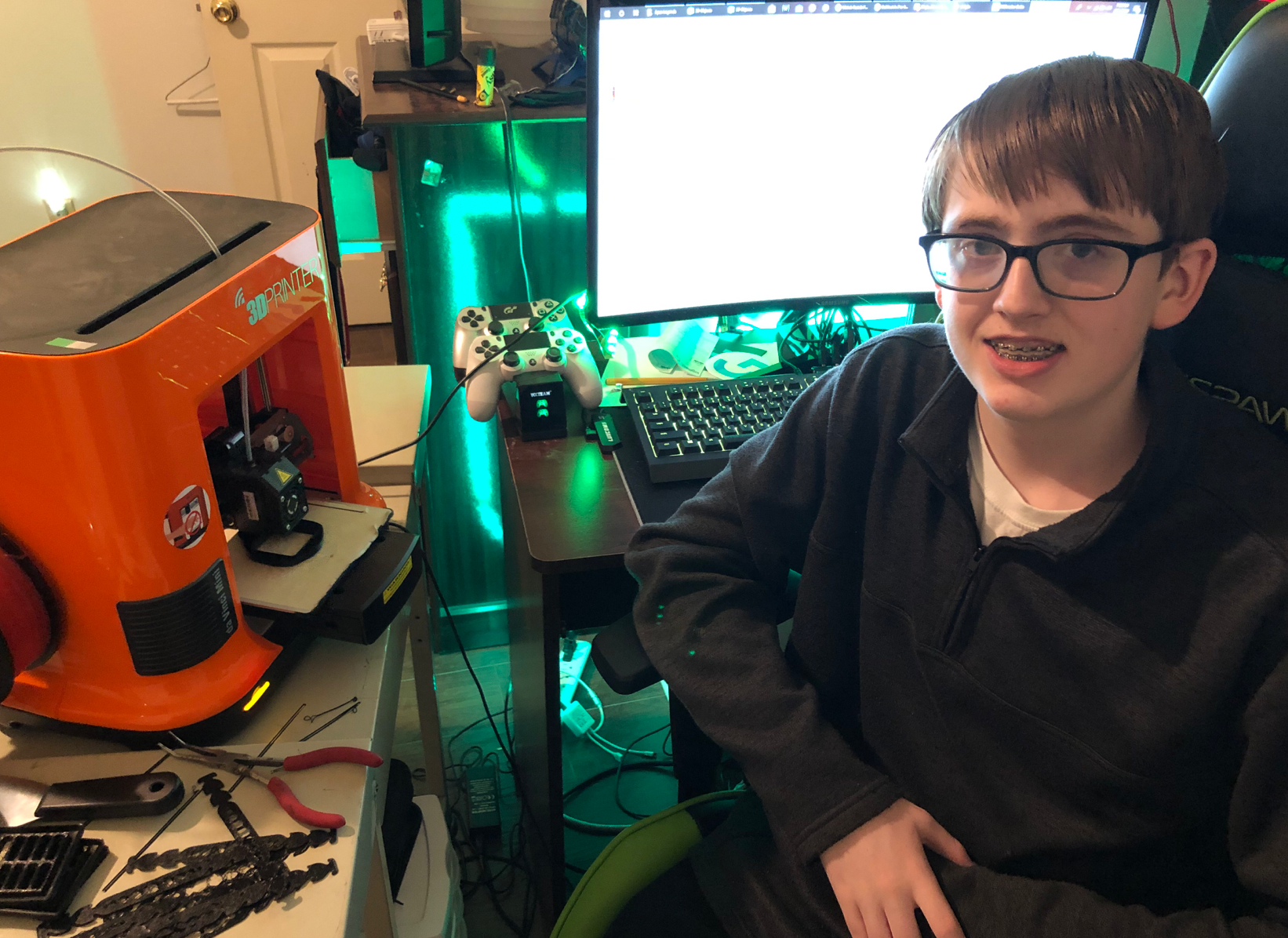

- Andrew Powell sits in front of his 3D printer. Powell is helping in the coronavirus relief effort by making personal protective equipment (PPE).

|

Getting your Trinity Audio player ready...

|

Technology and 3D printing have long been primary interests for 15-year-old Andrew Powell. Those interests were founded in his fascination with sci-fi. Today, Andrew is on the cutting-edge of technology that is helping prevent the spread of COVID-19 and potentially save lives.

Andrew, a dually enrolled student at Goshen High School and Enterprise State Community College, was recruited as a 3D printer for Troy University faculty staff and students who are working together to utilize 3D printers to address the current shortage in personal protective equipment (PPE) for healthcare workers.

Ed Noriega, who is heading the project, said the available printers were running 24-7 and the printing was painfully slow.

So, he said, a call went out to the community to anyone with a 3D printer who was willing to help produce PPE units.

“In looking for people with 3D printers to help print more units, Andrew learned about the need and he responded,” Noriega said. “HIs interest is in 3D technology and he likes to help others so the project was perfect for him and he for us.”

Powell said, with school out for the year and time on his hands, he had been using his 3D printer to make different items including bookmarks and keychains. He knew he could use the same technology to make the plastic masks to be used by healthcare workers.

“The plastic comes in rolls, in tubes,” he said. “The 3D printer works by extruding molten plastic through a nozzle, like a water hose,” he said.

The plastic is melted according to a 2D object and the printer forms the molten plastic into a specified hardened form.

“I have made six plastic masks and it takes about three hours to make each one,” Powell said. “The face shields takes less time, about two hours.”

The masks and face shields help protect frontline workers from potential virus-containing droplets released by coughing, sneezing and other close contact.

Powell said he is proud to have the opportunity to contribute to the making of masks for those who are on the front lines in the effort to slow and stop the spread of the coronavirus.

For Powell, the opportunity to be involved in the making protective equipment for those on the front lines in the fight against COVID-19 is one that he could never have expected but one that he takes seriously.

He plans a career in the field of technology and looks forward to the opportunities and challenges that it will present.

Noriega expressed appreciation to Powell and others who have made their 3D printers available for making plastic masks and face shields for those on the front lines of the battle against COVID-19.

“We continue to need 3D printers, especially the larger printers that are capable of making the face shields,” he said.

For more information, call Noriega at 334-672-2085.