3D printers create masks, PPE locally

Published 9:39 pm Friday, April 10, 2020

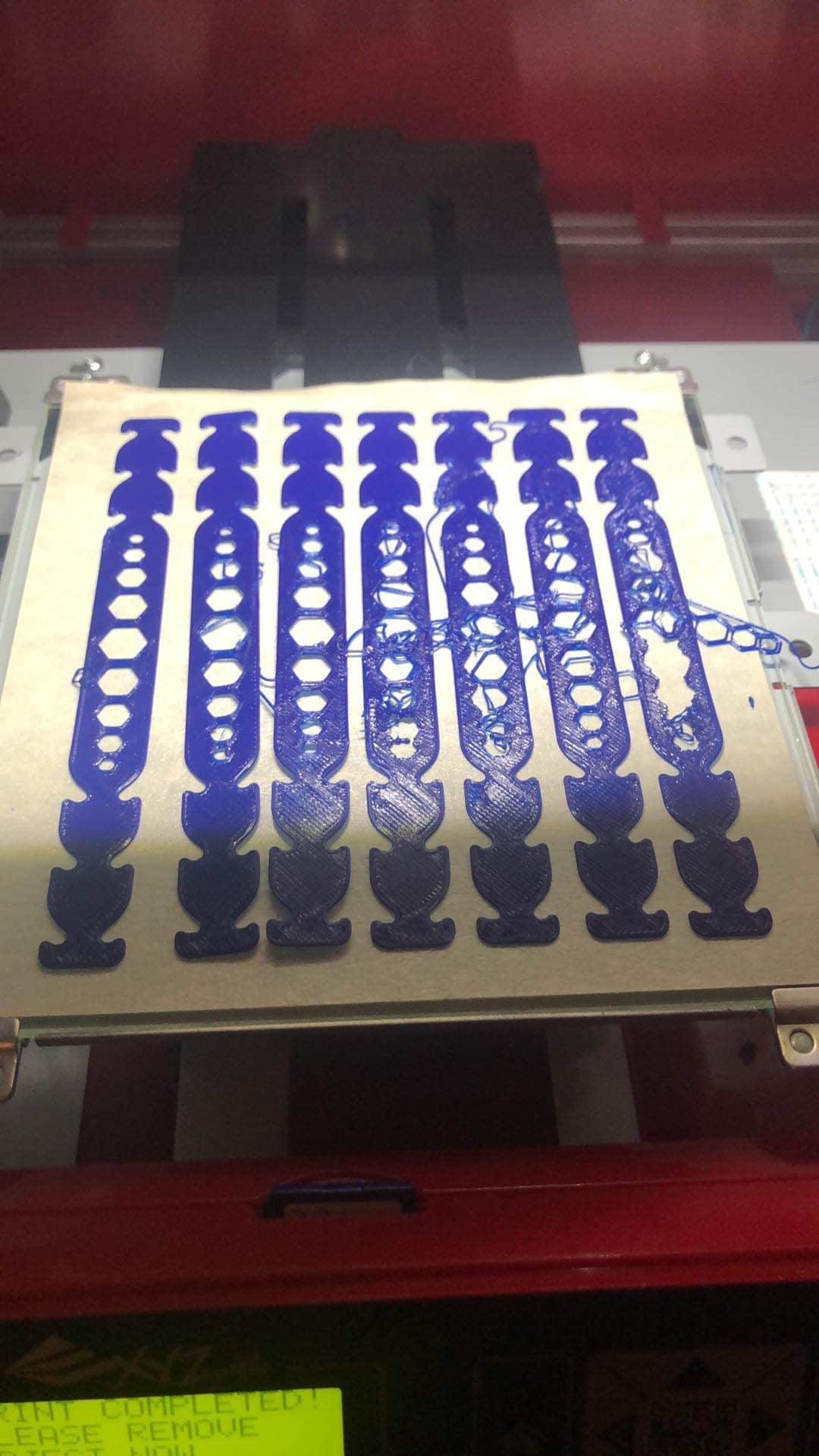

- 3D printing equipment at Troy University created these masks for local first responders and medical providers.

|

Getting your Trinity Audio player ready...

|

Troy University faculty, staff and students are working together to utilize 3D printers to address the current shortage in personal protective equipment, including face shields and masks, for local healthcare workers. But 3D printers are in short supply. and the community is being asked to help.

“Making the face shields and masks is very time consuming and we have a limited number of 3D printers,” said Ed; Noriega, a professor in the Troy University Department of Art and Design who is heading up the project. “We have six 3D computers that belong to Troy University and several that are on loan to us. But we are limited by the number of printers at our disposal.”

To meet the local need for face shields and masks, Noriega said those who have 3D printers are asked to make them available to those working on the project, including the Department of Art and Design, the IDEA Bank, the Broadcast and Digital Network and the Troy University Libraries and other university.

The need for face shields is urgent because of the short supply available for local law enforcement, fire departments and guards at the Pike County Jail.

“It takes about three and a half hours to make one face shield,” Noriega said. “The shield is a plastic covering for the entire face and is protection for medical personnel and first responders who come in close contact with those who could potentially be carriers of the coronavirus. We have made about 40 face shields with ear extenders that make them more comfortable to wear. The masks are made of cloth and cover only the mouth area but they take much longer to make. We have made four to five of those. However, the local demand for the masks is not as great.”

In order to increase production of the face shields and masks, more 3D printers are needed.

“We are doing a callout to our community to anyone with a 3D printer who is willing to help us produce the face shields and masks,” Noriega said. “Volunteers can print the items at home. Time is really of the essence. We’re good with them printing at home. They just to be on call when we’re ready to make the bigger production runs.”

There is no charge for the face shields or masks.

“This is not a situation where we’re planning on making money,” Noriega said. “Nobody’s getting compensated for this. We’re doing this to help. How can you put a dollar among on lives?”

Once the areas of greatest need are determined, Noriega and his colleagues plan on ramping up printing efforts. They have the capability to also produce gadgets for opening doors and pushing elevator buttons and key pads.

However, first things first. But, if enough 3D printers are loaned, the more that can be done to curb the spread of COVID-19.

For donations to support the effort, an account has been set up at https://www.gofundme.com/f/funding-for-3d-printing.ppe.